47 cm f5 mirror

Jan. 1999

I bought the 48 x4,0 cm Suprax low expansion disk from Beacon Hill telescopes in Cleethorpes (UK) . net price : 408 pounds

Spring 1999

I had a f5.1 radius generated in the disk by J.Eindhoven in the village of Buurse. Cost F175 ( 80 euro)

November 1999

As a grinding tool; I made a disk of plaster on top of the mirror disk. You make a dam of cardboard(2 mm thick) around the disk, tape it snug and apply a layer of Vaseline tot the cardboard and the mirror.

Making and casting the plaster (calcium sulphate) is something you have to learn first!

Too much water makes it too weak, too little water results in a mix you can’t pour!

By the way : it is much cheaper to buy the plaster in 20 kg bags than in small 2,5 kg bags in the building market.

Once you have filled the dam with plaster you have to make the top layer even with the help of a peace of wood.

Drying takes at least a week,according to my experience.I put the disc on a pile of newspaper to speed up the drying. Every day I changed the papers.

For my first try with grinding tools I glued 35x35x 8 mm ceramic tiles with epoxy resin on the plaster. First I had made a line drawing to give the tiles their proper place.

After the glue had hardened, I protected the plaster with poly urethane floor varnish (3 layers)

Dec.30 ,1999

First step: making the grinding tool fit the mirror.First try with mirror above and C240 wasn’t a success. The tiles are too high and the grinding powder stays too low.

Second try : mirror face up with a ¼ to 1/3 straight stroke and W-stroke is OK

One can follow the adaption of the grinding tool tot the mirror by monitoring the behavior of ink crosses on the individual tiles.

After 65 turns of C240 the majority of the tiles was still untouched.

C180 : after 155 turns still too many tiles untouched

Jan 17, 2000

I have enough of this tool

Another one is made , this time with much thinner tiles: 19x19x 2 mm.

270 of them were needed!. Tiles on the edge of the tool were partly nibbled away with a pair of pliers.

C320 : after 175 min of grinding (mirror above and below) only 20 tiles were untouched.

Total time 315 minutes for C320. That’s the time it took to get all the tiles in touch with the mirror and to grind out the larger pits.

Sept. 7, 2000

C600

- 60 min mirror above: ink cross stays very long on outside tiles

- 120 min : I add new carborundum suspension after every 3 rounds around the grinding post

Sep. 22: 330 min grinding time. All pits cleared

C800

Total time 125 min with mirror below and above

C 1200

The edge of the mirror is ground with a 400 stone

Total time 120 min mirror below and 40 min mirror above

Mirror surface looks OK

POLISHING

Feb. 5, 2001

The polishing tool is made of plaster (calcium sulphate) . diameter 40 cm, thickness 5 cm.

The plaster was cast on a 40 cm f4.5 mirror that was still in the grinding stage. It is coated with 3 layers of weatherproof varnish.

The molten pitch is cast on the surface (cardboard dam around the tool) and in the not yet hardened pitch channels are pressed with a coat hanger.

Polishng stroke : mirror below W-stroke ; 3 cm overhang (i.e. edge of tool passes 3 cm over mirror’s edge).

Polishing isn’t going well. Scratching the polishing squares is a great help for smoother movement of the lap

120 minutes : great scratch discovered!

The grinding tool is dug up again and grinding with C1200 starts again. Several other scratches are found; again the edge of the mirror and the grinding tiles are smoothed with the 400 stone

After 190 minutes with C1200 I am ready to start polishing again

POLISHING (second try)

This time a 48 cm pitch lap is made on a 48 cm plaster tool (cast on this mirror).

Pitch squares are 4x 4 cm . They are scratched with a sharp knife.

June 19 2001

Total polishing time ; 7 hours in periods of 15 min. all the time TOT.

July 1 Total time 17,5 hours . All the time mirror above.

Reflection test( 25 W clear bulb focused with 50 mm f2 lens) : weak in middle and on edge of mirror)

July 15

Pitch squares covered with fresh pitch, applied with a stiff brush. Squares scratched again.

July 23

Total polishing time 22 h 45 min Mirror above

Reflection test : very weak reflection(in dark room)

August 2

30 hours polishing time (mirror above) Reflection test: extremely weak.

Why all the time the mirror above? Iwas afraid of scratsches with the mirror below!

CORRECTION OF THE MIRROR

I build a rig for star testing the mirror. It was important to know whether the mirror was astigmatic.

Test on Polaris with 12 mm : no astigmatism

Correction to parabola:

I made the following pitch laps : 48 cm ( on plaster disc), 25 cm ( on plaster disc), 15 cm ( on glass disc), 10 cm ( on glass disc)

The pitch was Gugolz 55 + some old 64, softened with turpentine and linseedoil antil the hardness was 7mm /20 oC/ 1mm tip. This is a test mentioned in the book by Texereau(telescope making). The pitch was relatively soft.

Test of the mirror:

Ronchi : spherical with turned up edge region (several cm)

Foucault : diffraction ring completely around the mirror.

The mirror was placed on a 9 mm thick disc of foam rubber on a plywood base of 25 mm thickness on the polishing/grinding table.

Step 1

25 cm pitch lap with ceriumoxide

- large W-stroke with 5-7 cm overhang(that is, the edge of the lap over the mirror’s edge 5 5 turns

- straight stroke 0-1 cm from Center and 5-7 cm over. 20 turns

- W-stroke 5-7 cm over (also left and right 5-7 cm over) 5 turns

- Straight stroke 0-1 cm from center 20 turns

- W-stroke (like c) 3 turns

Test : Ronchi : lines start to bulge. No TDE or turned up edge.

In the meantime the thickness of the pitch is reduced from 7 to 4 mm! Obviously too soft. I scratch the pitch for a smooth movement.

Step 2

25 cm pitch lap

Strokes with 4-7 cm overhang

- straight stroke 0-1 cm left of C 10 turns

- id 10 turns

- W-stroke 3 turns

- like b 20 turns

Foucault:

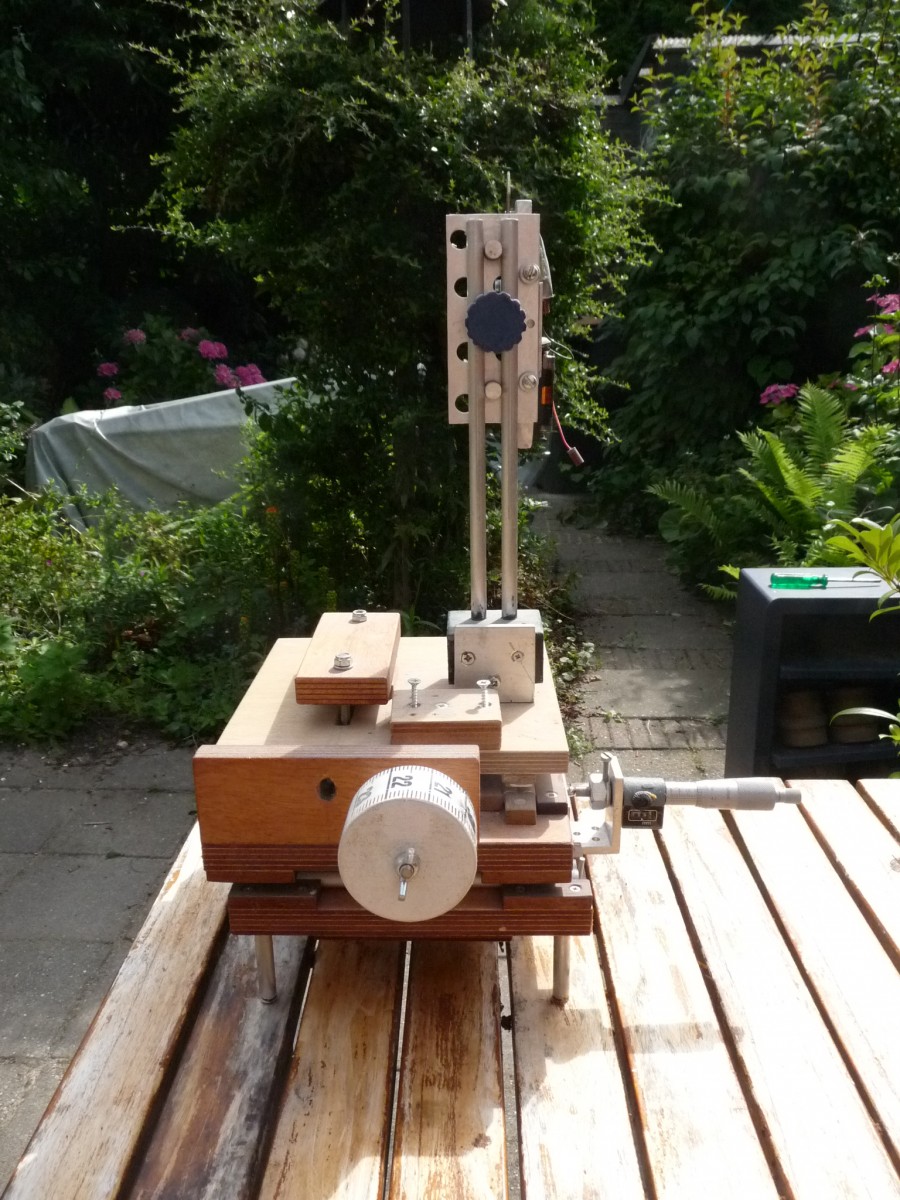

Picture of the tester(moving light source)

At the right you see the accurate micrometerscrew,necessary for reading the zones at 0,01 mm

Radius of curvature of mirror =4843 mm

Measurements of h2/2R

h = radius of zone and R=radius of curvature

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0 | 0,1 | 0,5 | 1,1 | 1,4 | 1,3 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Edge area turned up!

Step 3

- Increasing the correction:

15 cm soft pitch lap straight stroke 1-3 cm left of C

5 cm overhang …. 30 turns

2. 25 cm lap straight stroke 0-1 cm left of C; 5-7 cm overhang

10 turns

3. 25 cm lap : W-stroke 5-7 cm overhang (smoothing) 5 turns

Foucault :

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,39 | 0,78 | 1,22 | 1,82 | 2,23 | 2,3 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Step 4 Feb 3 , 2004

- Tapered 20 cm lap ( squares diminished towards the edge)

Soft pitch

Straight stroke 0-3 cm from C 5 cm overhang 4x 10 rounds

2. 25 cm lap

W stroke 5-6 cm overhang 5x 1 turn (cold pressing between rounds)

Foucault :

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,35 | 0,84 | 1,54 | 2,22 | 2,65 | 3,01 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

The outer zone are difficult to read properly. I am going to use a small telescope to view the zones.

Step 5

- Increasing correcton

20 cm lap straight stroke 0-2 cm from C 5x 10 turns

2. Outer zones

25 cm lap W-stroke 5-7 cm overhang 1 turn .

I made a new 25 cm lap. The old one was too thin.

Ronchi : parabola; weak zone (kink) several cm from edge

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,21 | 1,03 | 1,83 | 2,47 | 3,09 | 3,38 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Conclusion: flat center and high outer zone

Step 6

1. Deepening the center:

15 cm lap straight stroke 0-1 cm left of C 2x 10 turns

2. 20 cm lap ; increasing correction: straight stroke 0-5 cm left of Center 3x 10 turns

3. .Smoothing : 25 cm lap Wstroke 7 x 1 turn

All strokes with 5-7 cm overhang

Ronchi : flat edge and flat center

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,36 | 1,27 | 2,01 | 2,85 | 3,56 | 3,91 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Step 7

a.

15 cm lap: deepening the center: straight stroke through C : 15 turns

b. narrow W-stroke : center of lap between r=5 cm left and right : 3 turns

c. 48 cm lap 1/3 narrow W-stroke Mirror below : 3x 1 turn

d. 48 cm lap : correcting the high edge: ½ straight stroke (overhang12 cm) : 1 turn

It is necessary to scratch the pitch squares to be able to polish properly. Otherwise movement is very jerky.

Ronchi : flat edge and spotty center

Fouc: 2-4 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,94 | 2,11 | 2,93 | 3,58 | 4,32 | 4,79 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Step 8 feb 7 , 2004

- 20 cm lap W-stroke with emphasis on the outer zones 3x 1 turn

- 15 cm lap

circular stroke 1. edge area: 10 rounds b . from r= – 1 to r= 20 cm 10 turns

Ronchi : high outer zone

Foucault : measurements with the help of the little telescope(3x) are more consistent

3-4 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,91 | 1,93 | 2,61 | 3,37 | 4,08 | 4,50 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

The correction is lessened by working on the edge

Step 9

Increasing correction

- Tapered 20 cm lap (with narrowed edge facets)

Straight stroke 0-1 cm left of C 15 turns

2. 20 cm lap W-stroke 3x 1 turn

48 cm lap :

3. smoothing 1/3 straight stroke 2 turns

4. ½ straight stroke 2x 1 turns (pressing between turns)

Test

Ronchi : worse : parabola but quite a big bulge around the central area

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,75 | 1,66 | 2,38 | 3,20 | 3,88 | 4,26 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Labda/2,5 wavefront error

Step 10 feb 8

Deepening the center

- 15 cm lap (facets narrower at edge)

Straight stroke on center 5 turns

2. straight stroke 1-4 cm left of C ; 10 turns

3. 20 cm lap (facets narrowing at edge) W-stroke within the mirrors edge ;light pressure 5 turns

4. 48 cm lap1/4 W stroke with pressure on edge: 1 turn

3 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,48 | 1,35 | 2,05 | 2,82 | 3,59 | 4,08 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Edge somewhat better

- Correction lower as a result of the W-stroke and the big lap

Step 11

- Increase the correction!

15 cm lap straight stroke 0-1 cm left of C and 5 cm overhang : 2×10 turns

2. 15 cm lap narrow W-stroke 2,5 cm left and right movement and 5 cm overhang

2 turns

3. 48 cm lap mirror MOT ½ straight stroke 2 x 1 turn

3 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 1,02 | 1,75 | 2,67 | 3,30 | 4,05 | 4,62 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Figure : central hill and turned up edge area

——————————————————————————————————–

Step 12

- Working on central hill

20 cm lap with narrowed facets at the edge: narrow W-stroke with 2 cm movement to left and right 3x 1 turn (pressing in between)

2. 48 cm lap MOT ½ straight stroke 3×1 turn

3 measurements

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,87 | 1,50 | 2,34 | 3,08 | 3,94 | 4,65 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Step 13

Turned up edge area is diminishing

- 15 cm lap straight stroke 0-1 cm left of C 5 turns (5 cm overhang)

- New 15 cm lap : narrow W-stroke (2,5 cm left and right) 3x 1 turn

- 48 cm lap narrow W-stroke : 3x 1 turn

2 measurements; close together (differ only 0,05 mm)

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,85 | 1,61 | 2,35 | 3,10 | 4,06 | 4,79 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Edge area becoming lower

Figure peak to valley labda/5.3

Step 14

15 cm lap : deepening the center

- straight stroke 0-3 cm left of C and 5 cm overhang 10 turns with light pressure

2. narrow W 5 cm movement left and right. Edge of lap moves till r=15 -16 cm

2x 1 turn

3. Smoothing : 48 cm lap1/2 to 1/3 W-stroke ; mirror above ; 2×1 turn

| Zone | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Measurements | 0 | 0,85 | 1,72 | 2,37 | 3,29 | 4,23 | 4,91 |

| Parabola | 0 | 0,98 | 1,81 | 2,63 | 3,45 | 4,27 | 5,05 |

Strehl = 0,982 Peak to valley 1/13 labda

Star test ; with 33 % central mask image inside and outside F very similar

Ronchi on star : 3-4 straight lines

Aluminizing : Ernst Befort in Wetzlar Germany. Cost for 94 % enhanced coating : 400 euro net (june, 2004)